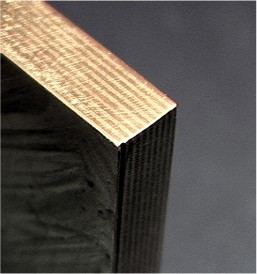

More than just surface, the pattern in mokume goes entirely through the piece; the pattern is not on the material - it is the material. Unlike so many modern products, mokume is permanent. The design is the content, the intention the reality. Different metals used in the pattern may react to various environmental elements such as atmospheric moisture or the oils of one's skin. This reaction can slowly alter the colors of the metal adding an element of uniqueness and, in a way, creating a direct relational link between the work and the wearer. A basic cleaning will reset the work to its original colors at any time. In the 17th century the Japanese metalsmith & master swordsmith Denbei Shoami developed the mokume technique to complement the layered steel of japanese swords. In mokume layers of various non-ferrous metals are fused together under heat and high pressure. This yields a block of material known as a billet. The billet is carved, forged, stretched, twisted, and etched in any number of combinations or directions in order to make unique patterns.

The custom knife combines beauty, function, and permanence. I aim to make knives which are beautiful, can handle rigorous use and which are somehow intimately connected to their owners. The knife pictured here has a forged high carbon steel blade, an ebony, buffalo horn and brass handle, and mokume fittings. The sheath is shaped half-tanned leather in the Scandinavian puukko style.

In a world of disposable goods, the fine metal object stands out as a mark against time. Most objects are designed to meet the needs of temporary fashions and their meaning, depth, and ability to provide an ultimate sense of satisfaction is limited. Fine metal objects provide content through quality, permanence, effort, and care.

Handmade jewelry should go further than just decorating the body: it should be unique and suited to the wearer. It should elicit something beyond itself, and reward closer inspection. This silver/copper mokume ring is an example of jewelry made for a customer.

I studied English Literature in college, but became distracted by the machine shop. My first knife was born of this distraction and the help of the department's machinist. Simultaneously, I started going to knife shows, where I learned even more. I taught in a high school for two years, then decided to attend art school at the Maine College of Art and take up metalsmithing. Currently I'm part of the AU3 goldsmithing studio in Helsinki.

Helsinki, Finland

www.au3.fi